Aerial tramways / compact aerial tramways

Best performance Swiss Made

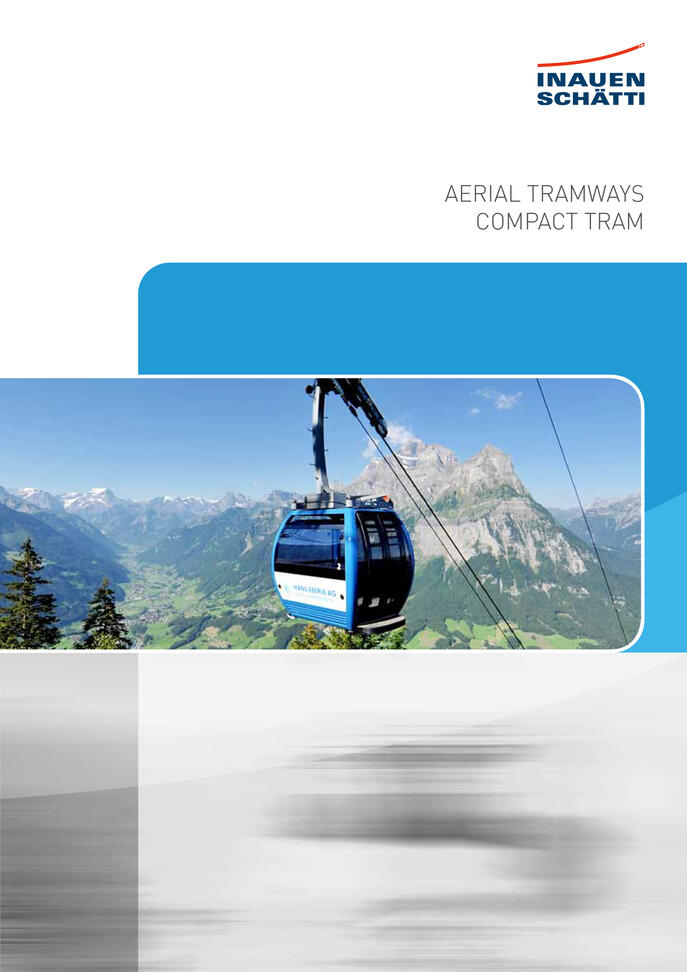

Aerial tramways are a reliable, efficient and ecologically sensible means of traffic and transport, with best performance on any terrain.

Aerial tramways are among the most secure and most popular means of traffic in Switzerland. Hardly any passengers will think about how much experience, know-how and technology accuracy has to go into the design, construction and maintenance of reliable aerial tramways while riding it. We think about these things, and meet the challenges our customers pose to us with their individual demands. You may always expect top performance from us. From consulting to construction to maintenance. Everything from your expert for secure travel up and down.

Flexible in any situation

We at Inauen-Schätti have specialized in the development and construction of sophisticated reversible bicable aerial tramways. This is a very compact aerial tramway system that permits access in difficult terrains like wide valleys, cliffs or even residential areas. Thanks to its great flexibility, our compact aerial tramway can be used in any imaginable area, from rough mountain regions to vantage points and remote properties, to urban traffic, beaches and coastal regions above cliffs.

Systematically efficient

The reversible bicable aerial tramway system has two cabins going synchronously back and forth between the two end stations. The «lane» is a carrying cable that is firmly anchored at the stations. A towing cable runs in an endless loop over rollers at the supports and in the end stations, moving cabins sized for up to 15 persons back and forth. Our reversible aerial tramways are particularly characterized by sophisticated technology innovations and high energy efficiency. Zero CO2 emissions in regular operation are also great ecologically.

At a single glance

- modular build as a basis for the cost-efficient individual configuration

- energy-efficient lane system

- CEN-compliant for the best safety

- access to difficult terrains

- high flexibility

- project-specific engineering

- service-compatible construction

- Accessible

- high degrees of freedom for the architect

- no CO2-emissions in regular operation

8-ATW 8 passenger aerial tramway

Comfort and safety at the highest level. With state-of-the-art cabins and innovative technology, your passengers will safely reach any destination.

15-ATW 15 passenger aerial tramway

On top with state-of-the-art technology and pioneering innovations: With cabins equipped to your wishes and requirements.

Conversion & renewal

To ensure availability and security of the facility, older ones often are refurbished and revised entirely. With our comprehensive competence, we develop your optimal solution from simple rope change to complete replacement of the system.

Special aerial tramways

Our special aerial tramways are often used in power plants, shaft facilities but also in industrial applications. These aerial tramways are also built according to the latest laws, directives and regulations.

Higher, farther, innovative

Technology through which good ideas become ingenuous ideas: This is the passion that drives us at Inauen-Schätti.

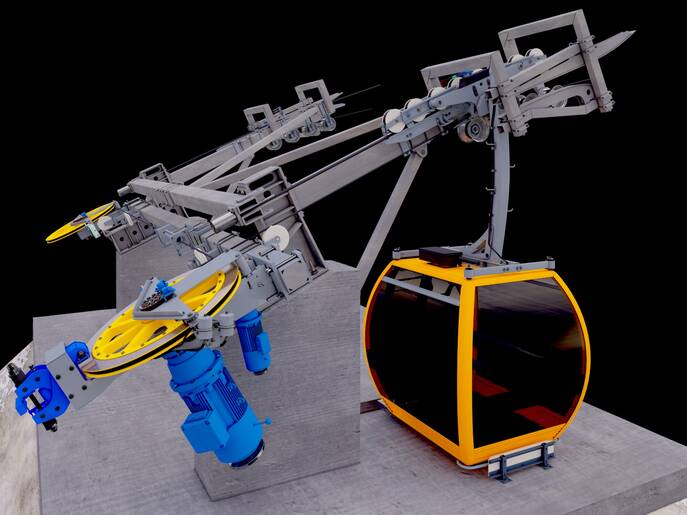

Why develop something that is already good even further? Because what is good can become even better. Following this principle, we have re-defined and perfected an established concept. Our compact aerial tramway system is based on the most innovative of technology, permitting setup of the entire station on only two concrete supports. The compact form and simple installation permit well-structured and well accessible placement - in contrast to large and difficult constructions -, do not require any additional drive rooms and are very low-maintenance.

Convincing technology

The compact drive of our reversible aerial tramway system needs very little space for drive frame, cable sheave, gear, electric motor and gyrating mass, as well as two brake systems that are independent of each other. The safety brake, mechanically pre-tensioned and hydraulically lifting, acts directly on the drive sheave, while the operating brake is directly integrated in the electrical motor depending on situation and adjustable or attached to the gyrating mass.

The carrying ropes are firmly anchored with casting sleeves and carrying rope bollards. An attached reel contains the carrying rope reserve and facilitates pushing of the cable. The towing cable is also firmly tensioned and has a re-tensioning device. The cables are guided across support arches with swing bearings on solid tube or scaffold supports.

The aerial tramway is controlled by safety technology on the highest level. This includes a state-of-the-art drive control with frequency converter, audio/video monitoring, remote access (for remote inspection and repairs) and many other options. Depending on local requirements, operation without staff on site is possible as well.

Assembly and commissioning

Warranted function We can always keep this promise with our efficient assembly technology and experienced specialists.

Even the best aerial tramway system will only work perfectly after being professionally installed and commissioned. We will do this for you with our experienced assembly specialists, certified engineers and a professional infrastructure. We will deal with setup organization, deployment and logistics and ensure that your operating staff will be familiar with the technology and function of aerial tramway operation from the first - for your system to run smoothly.

Professionally set up...

Time equals money. Save both with the very short assembly times at the construction site of your aerial tramway system. On the one hand, our experienced and competent assembly staff works very efficiently. On the other hand, and in particular, the installation time is reduced by the assembly-compatible construction of the individual components, as well as by use of standard modules that are pre-manufactured, pre-assembled and adjusted as far as possible in the factory.

...and set.

The first run is a great event and reason for joy. At least as long as your aerial tramway reliably works. Therefore, we will commission the system together with you and your team. It is also decisive that your operating staff knows about all the details of the system's technology and function. Our engineers will convey this know-how to your employees in specific on-site trainings. Set like this, your aerial tramway will run perfectly smooth.

Old becomes new

State-of-the-art technology for older plants. To enable best performance in future as well.

Only technology at the latest state of the art is technically and economically competitive. However, outdated systems do not have to be replaced and re-constructed entirely. Our core competences include conversions and retrofitting of aerial tramways with state-of-the-art components. This way, even older aerial tramways will meet the current demands again.

Modular modernizations

Older aerial tramways often no longer comply with the latest safety requirements. However, you do not need to replace them entirely. If possible, we will retrofit such systems with state-of-the-art standard components. As long as the building substance and infrastructure are still intact, the old drive can, for example, be replaced by a state-of-the-art standard drive module from our compact aerial tramway construction kits, including new brakes and emergency drive, to achieve best performance again.

Just retrofit

Replacing few complex components makes it possible to easily retrofit your aerial tramway technically once it has reached a certain age. Cable sheaves, for example, used to be produced as sophisticated welded constructions. Over time, the welded seams become susceptible to fatigue cracks. Older cable sheaves with steel grooves rather than rubber lining may also still be in use. In such cases, we can retrofit your aerial tramway with new cable sheaves from our standardized construction kit system virtually in the blink of an eye.

At a single glance

- conversion of old systems

- retrofitting of old systems with state-of-the-art components

- use of standard components

- efficient installations

- saves time and money

- short downtimes