Cable Installations Systems

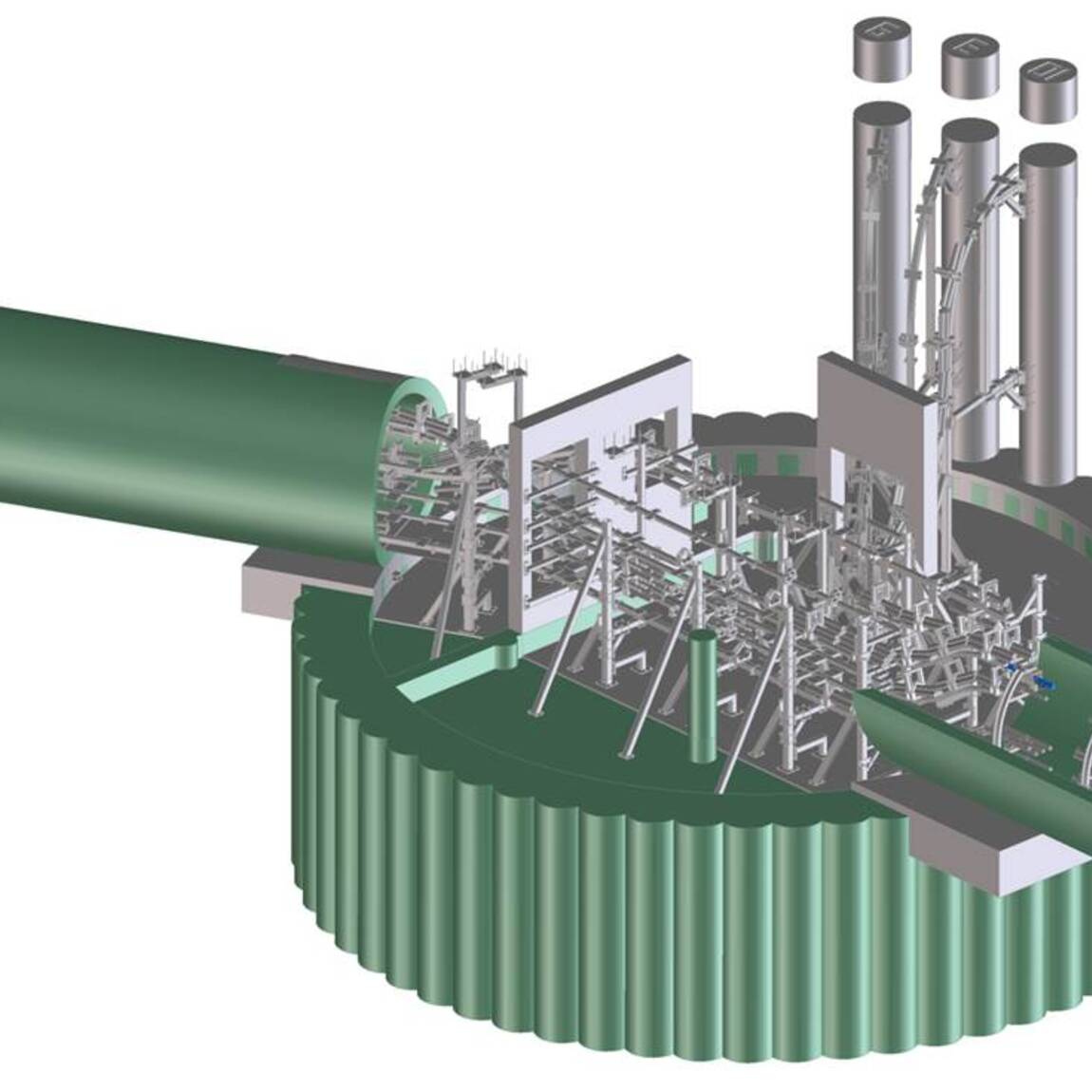

A cable installation system as a masterpiece

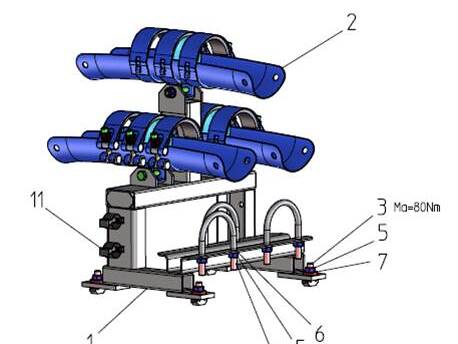

Attachment and installation technology

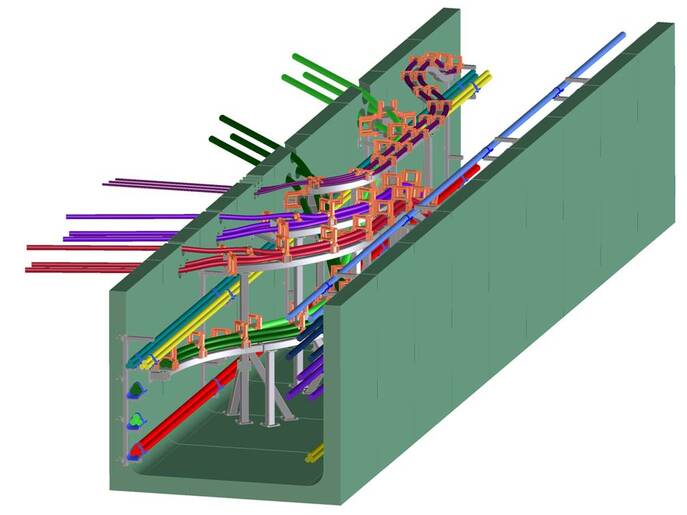

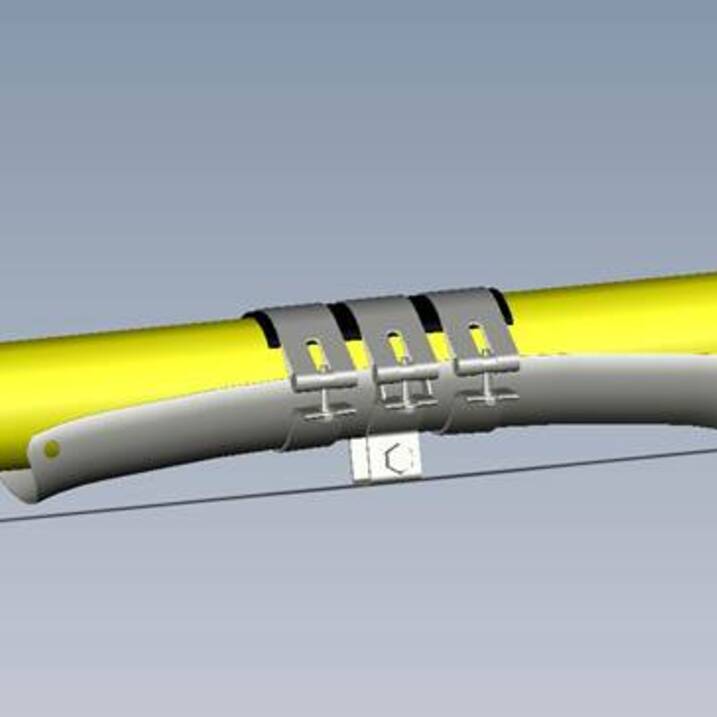

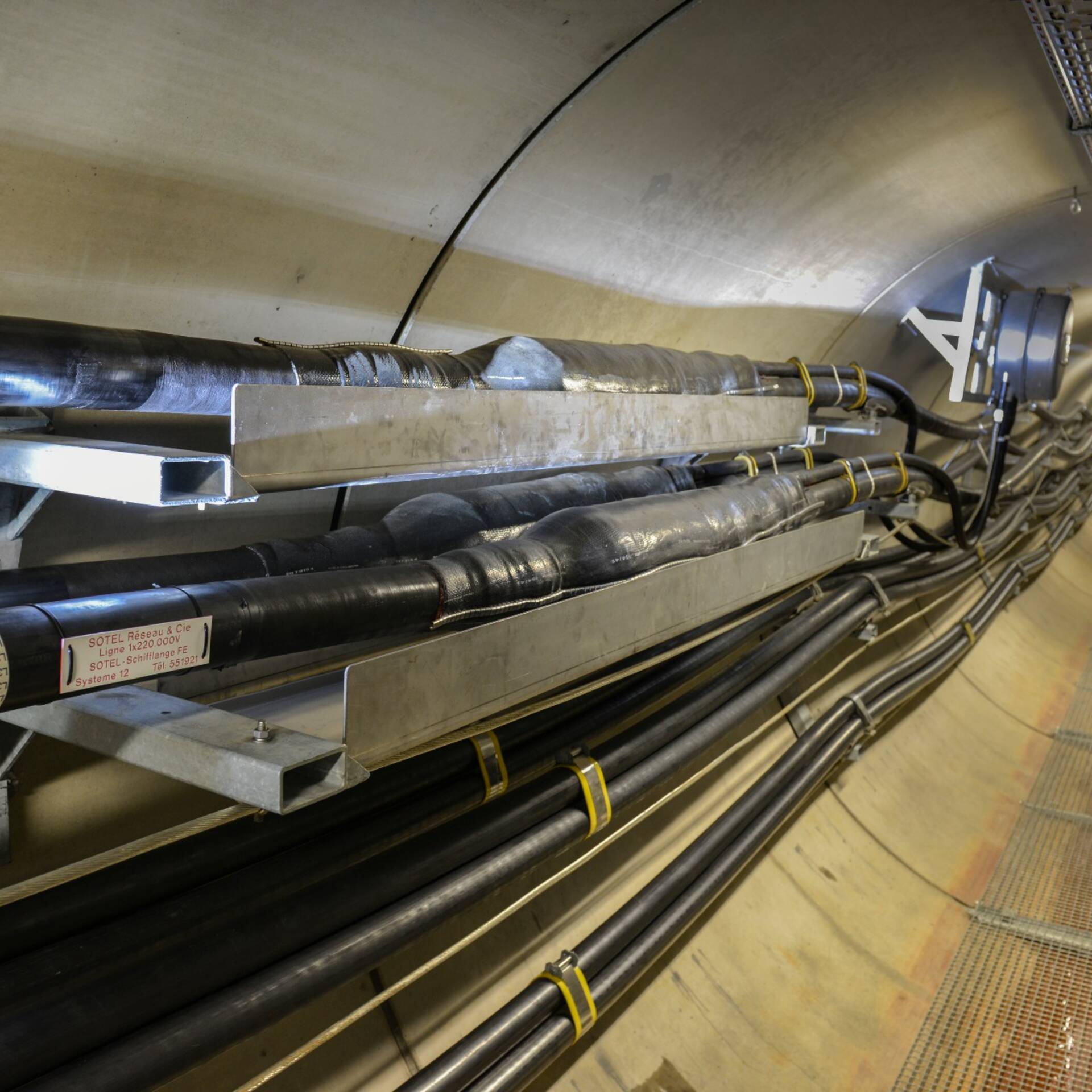

The «Streiff» cable installation system offers the option of directly inserting heavy high-voltage cables (110 to 500 kV) with weights of up to 40 kg/m in the cable saddles intended for final storage in a single work step.

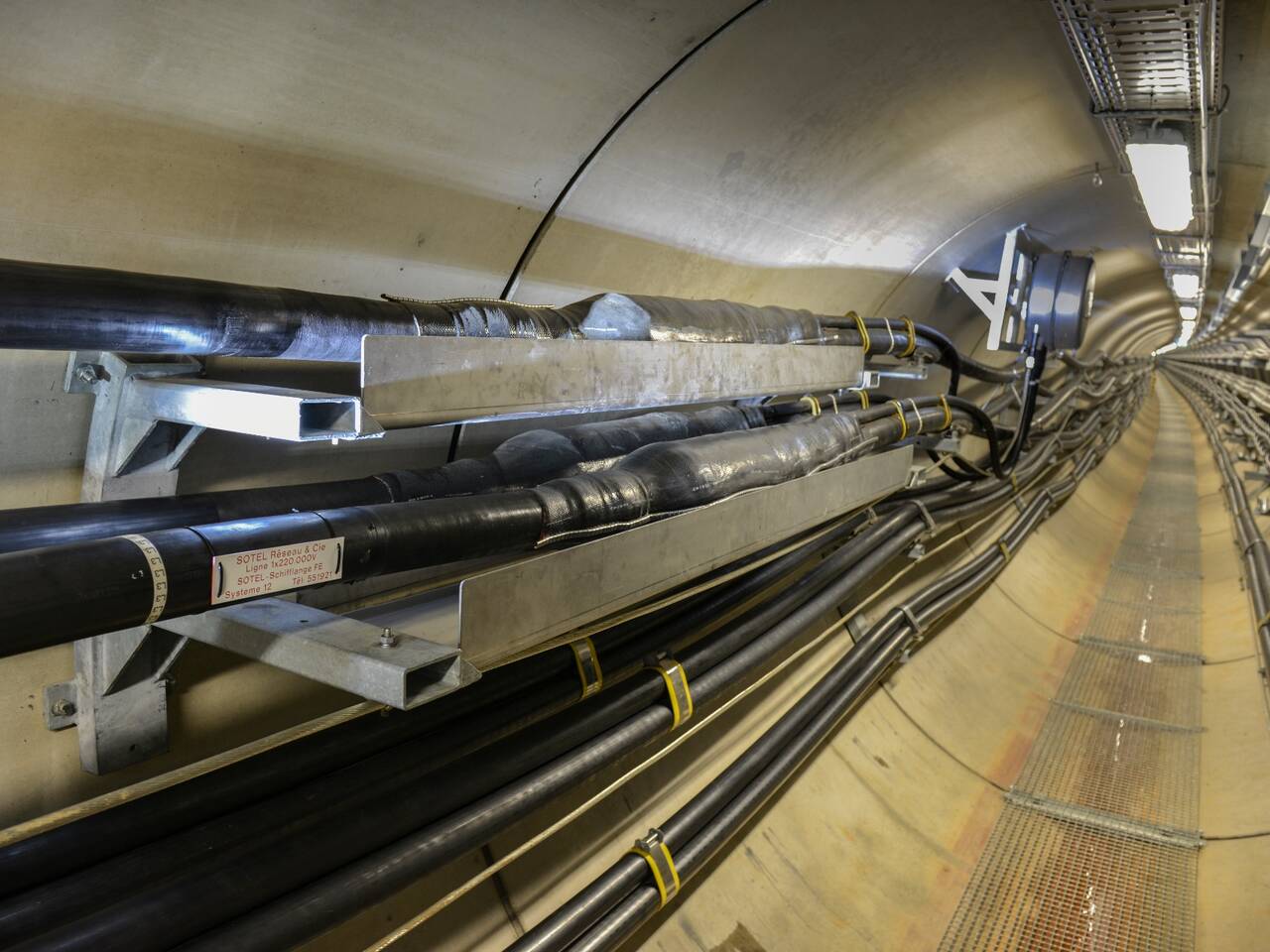

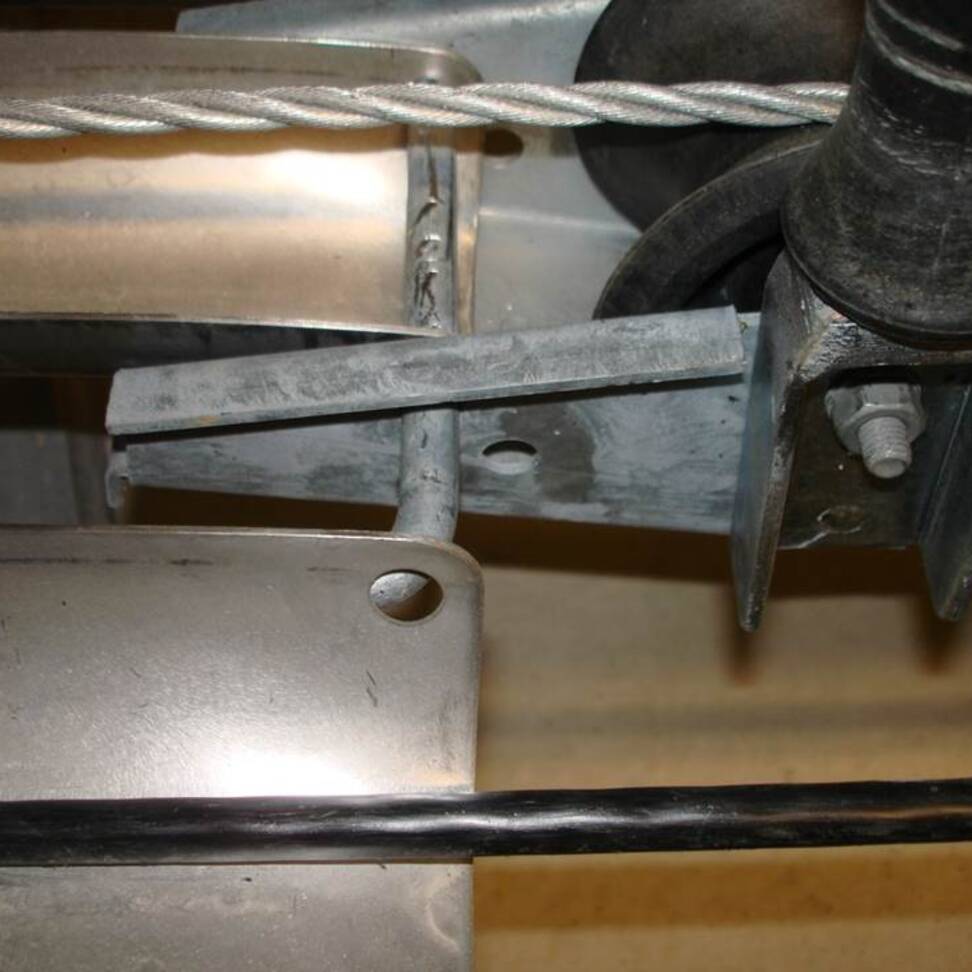

The cable rolls through the attachment system on «ball bearings» with a low friction resistance across long distances of approx. 500 – 1000 m, depending on cable size. This leads to very low pulling forces. The saddle distance is, depending on the properties and diameters of the cable, up to 7.2 meters. After insertion, the cable is placed in its final position in the anti-magnetic cable saddles. Only the sag will still be regulated after this.

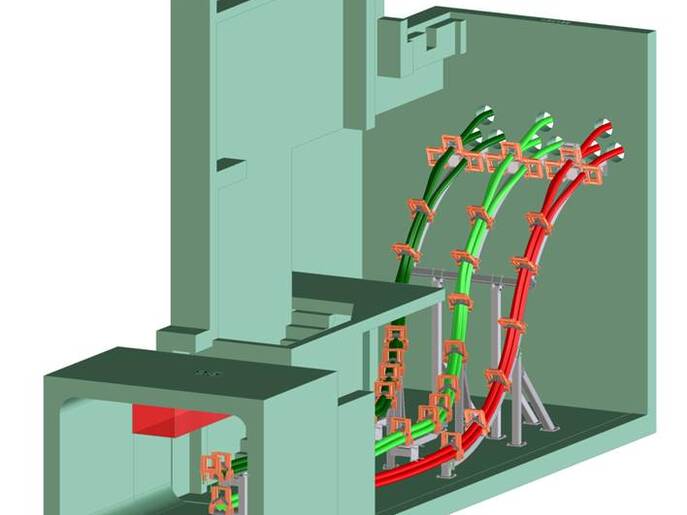

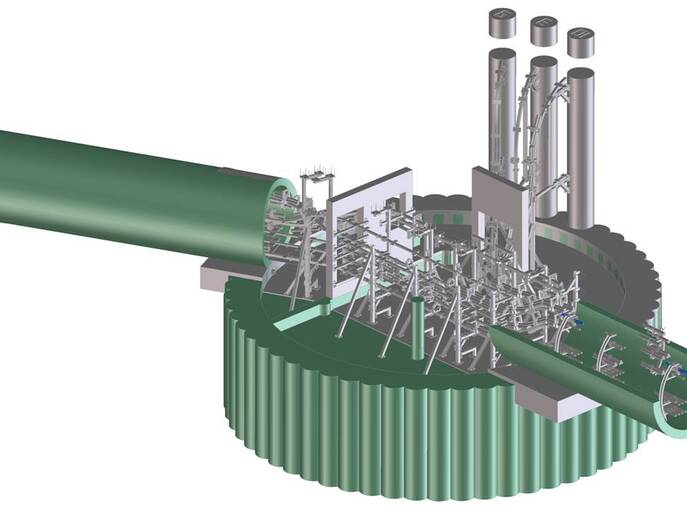

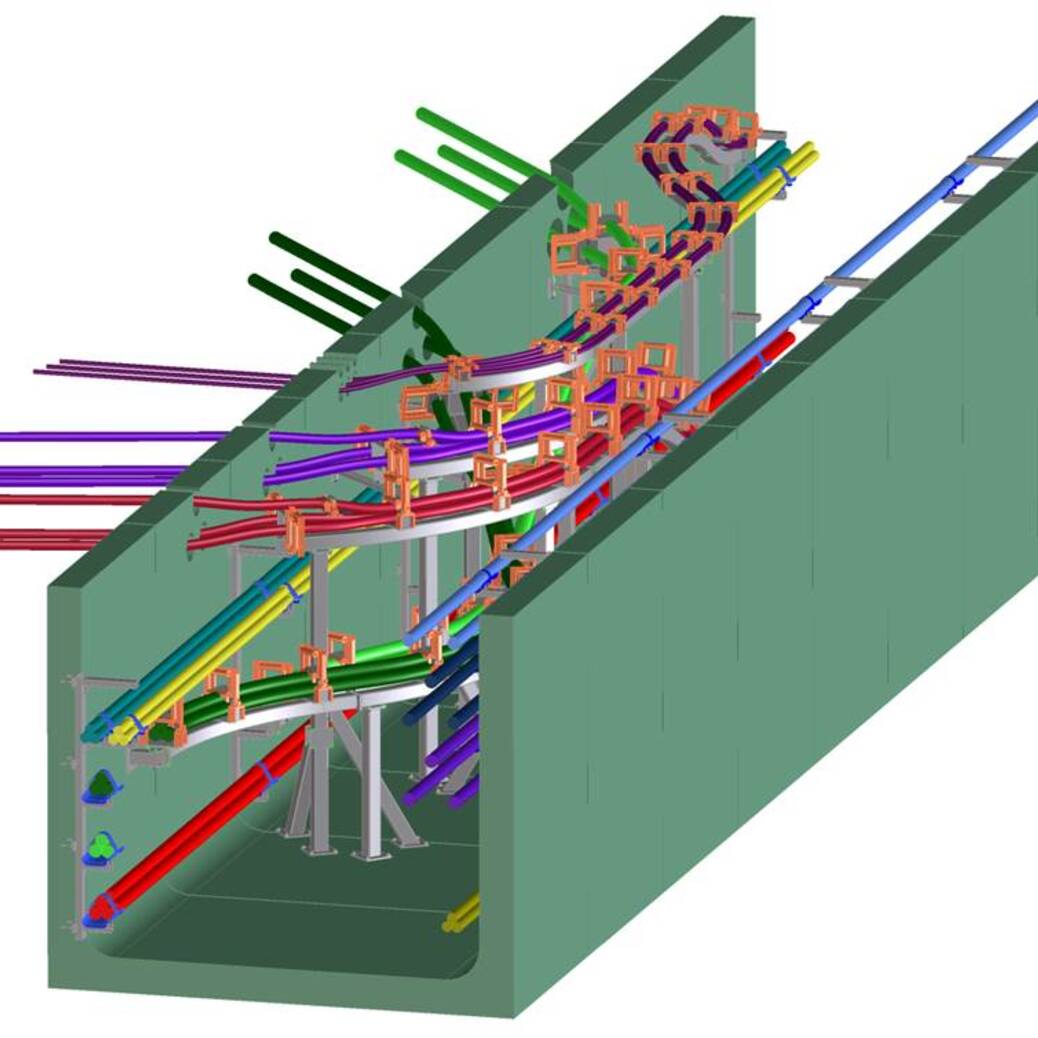

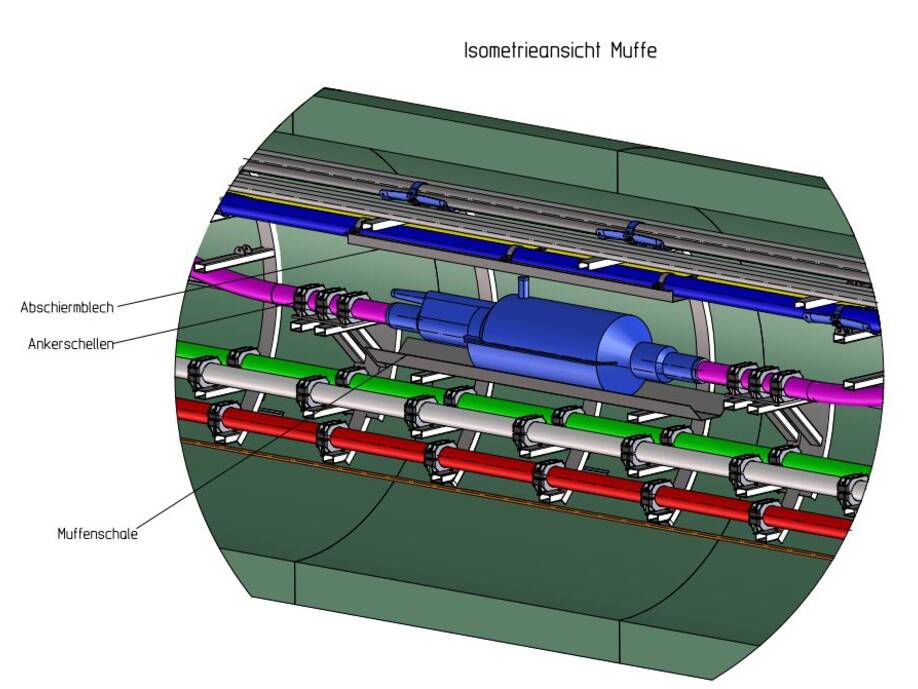

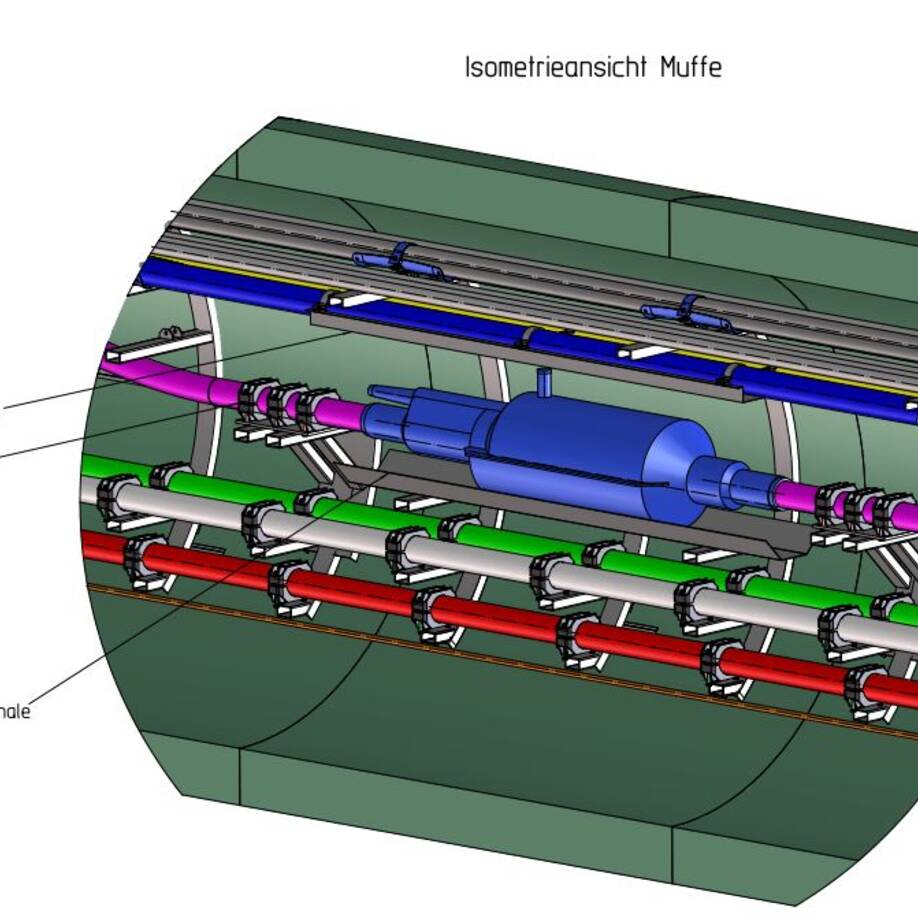

We also fully plan the sleeve positions, roller bends and transfer buildings in 3D-CAD to prevent surprises. This strongly increases planning safety and has a positive effect on the building costs.

Advantages:

- Simple project planning and planning safety by using state-of-the art planning media / recently including a virtual-reality system as well

- Simple and quick installation

- Direct insertion of the cable in the final location

- Optimal protection of the cable

- Low personnel demand for cable insertion

- Lowering the assembly costs

Engineering

Use of 3D-CAD and virtual reality has proven its worth many times already.

What would a building project be without detailed planning? We do all that we can to ensure that your planned system can be installed and assembled on the construction site without any issues, too. For this, we use 3D-CAD and plan all steps and installations in the virtual space. The high benefit results from planning safety. Communication is made much easier in the planner team due to this, and the virtual-reality system can be included where necessary.

Route buildings with the "Streiff" system

Comprehensive versions and implementation options

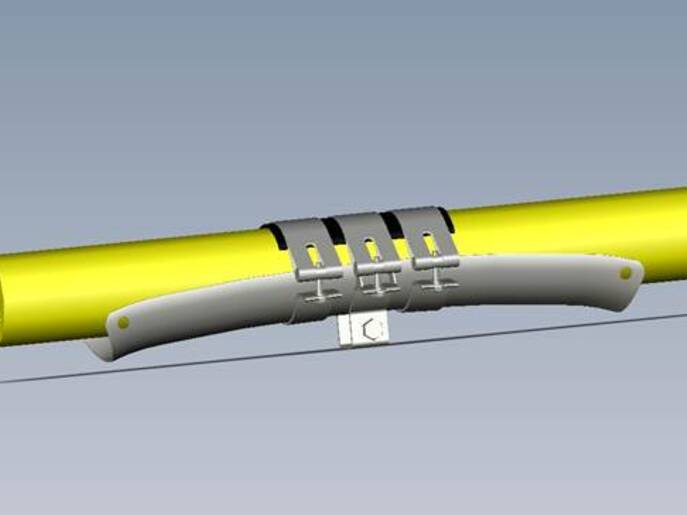

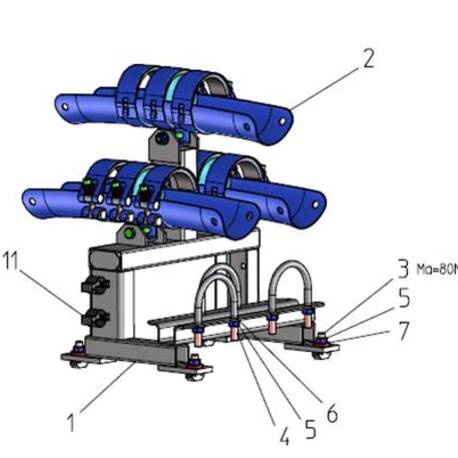

There are various saddle shells and attachment systems for the cable arrangements. Special saddle shells with reinforced attachment points are used for step routes. Cable bunches can be attached in a narrow triangle in the cable saddles as well in addition to a simple routed cable. The cable diameters are usually at 30 - 165 mm. Ask us if you need any other dimensions. Of course, we will design and deliver the wall brackets and further accessories, such as fall rollers, assembly rollers, booms, clamping bands, rubber inserts, etc. as well. We will gladly detail the project with you.

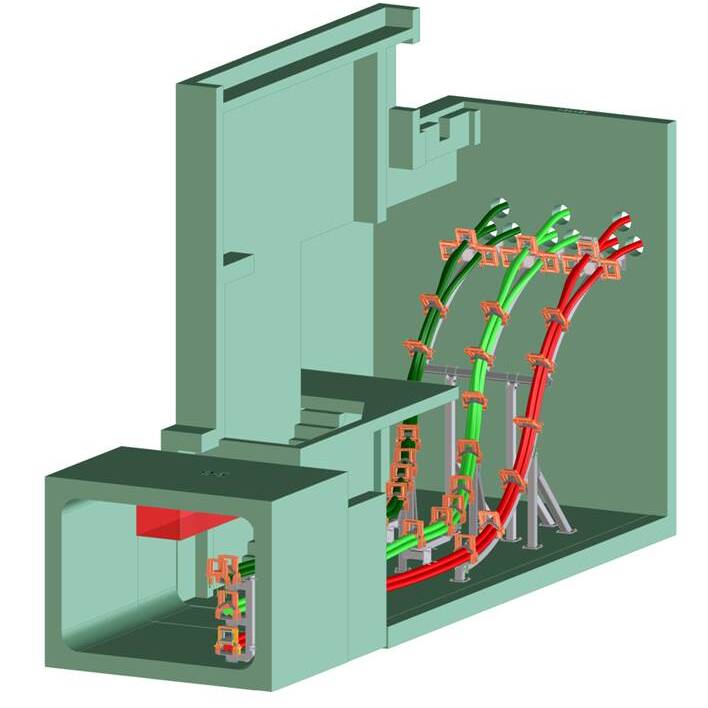

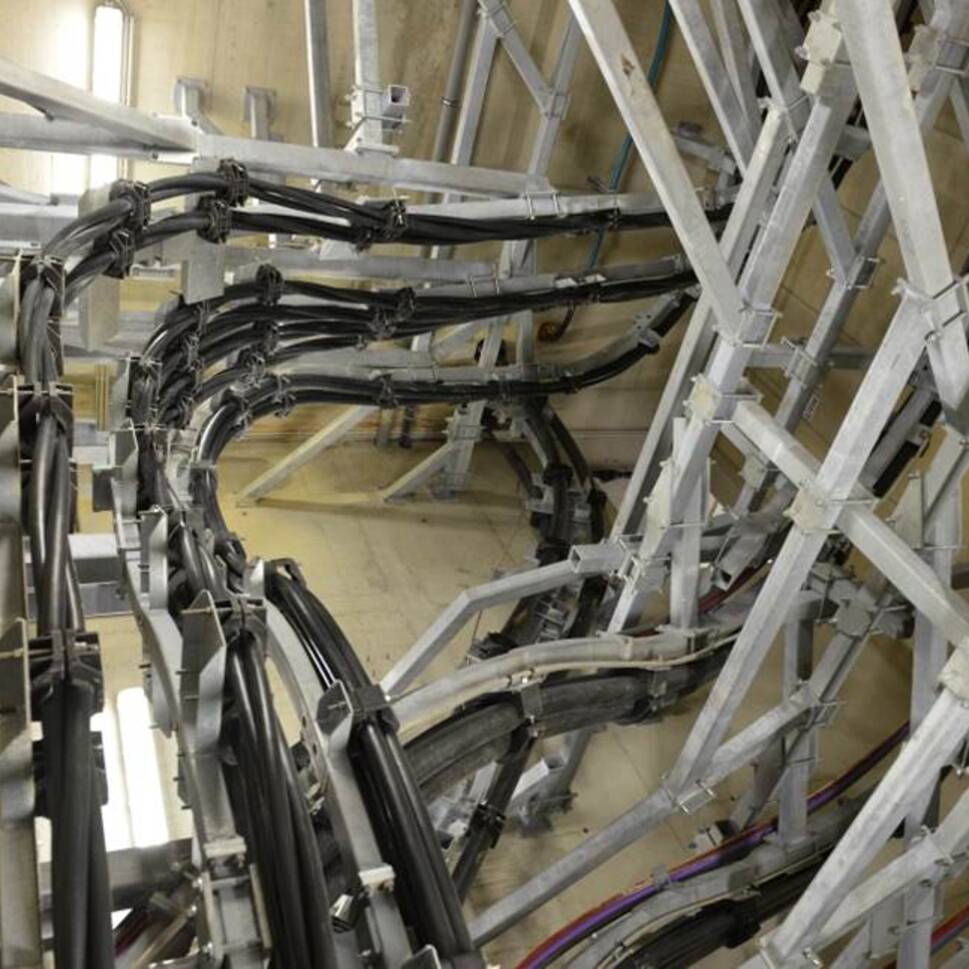

Cable input and transfer buildings

Comprehensively planned and implemented

Sometimes, things get narrow and chaotic. There are no compromises in a transfer building or at a cable input where careful cable treatment is concerned. Therefore, high precision and the possibility of adjustment must be considered in these buildings.

Sleeve places

Spacious, short-circuit-proof, easily accessible

Sleeve places should be spacious, short-circuit proof and easily accessible. For attachment of the earthing box, we also supply specific attachment consoles.

Accessories

Let our specialists advise you. No matter if you need spacers, rope pulleys or other tools: we will gladly review your request and your needs.

Assembly

Low personnel demand for cable insertion.

Since the cable is inserted into the ducts and tunnels in the final position and only needs to be attached afterwards, you can save plenty of time and staff. After the insertion, only the sag is adjusted, and the clamps are screwed shut.